MULTI ROLL BELT PRESS

Malvern Engineering Works offers the robust and popular models of multi-roll belt press manufactured in the USA by Phoenix Process Equipment company (www.dewater.com). Malvern Engineering works are the authorised sales representative for Phoenix Process equipment company, USA and are also maintaining their machines at the sites where they are installed. OEM spare parts are also available from us.

Features:

- Heavy all-welded main frame

- Modular construction

- Continuous automatic operation

- Open design

- Epoxy over zinc coated frame

- Pneumatic belt tracking/tensioning

- Standard, extended, independent or dual gravity zones.

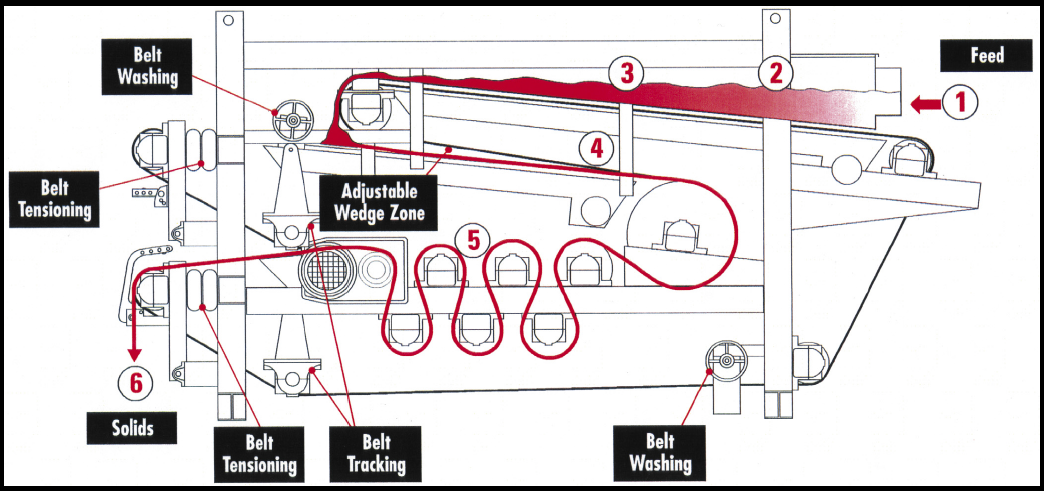

Process Description:

- Preconditioning (Flocculation): Most applications require the addition of polymers to the slurry prior to dewatering. The addition of these flocculants results in the agglomeration of solids, releasing free moisture. An inline mixer is provided for proper dispersal of polymer into the feed.

- Feed Distribution: The slurry is fed to a specially designed head box, where the material is evenly distributed for more efficient use of the filtering area.

- Gravity Drainage: Free moisture is separated from the solids by drainage through the moving filter belt.

- Wedge Pressure: Material advancing from the drainage zone is deposited into the wedge zone. Pressure is gradually applied as the upper and lower belts converge to form a “cake sandwich.”

- Compression/Shear: The belts then follow an “S” path through a series of compression rollers. The surface pressure created by belt tension squeezes additional moisture from the solids. Simultaneous shearing of the material opens additional voids for moisture release. The belts part, leaving a dry cake.

- Solids Discharge: Cake is separated from the belts by doctor blades and discharged.

Benefits:

- Assures component alignment.

- Allows variable roller configuration for maximum process flexibility.

- Minimal operator attention. Low maintenance requirement.

- Allows easy access to all components.

- Maximum corrosion protection in adverse conditions.

- Clean, safe operation. Greater reliability.

- Effective dewatering performance.

Application:

- Coal Refuse

- Scrubber Effluent

- Pulp and Paper Effluent

- Domestic Biological Waste

- Textile Wastewater

- Grease Trap Waste

- Water Treatment Sludge

- Aggregate Tailings

- Food Process Waste

- Chemical Waste

- Municipal Wastewater

- Dredging Slurries

Schematic Diagram: