Malvern Engineering Works, South Africa, offers high and low intensity magnetic roll separators required in the mineral, pharmaceutical and chemical industries.

Using over 75 years of process knowledge, computer added magnetic modeling software and in-house laboratory facilities, Malvern are able to offer flexible and cost-effective machines to suit our customer’s needs and objectives.

Malvern Engineering Works, South Africa, offers high and low intensity magnetic roll separators required in the mineral, pharmaceutical and chemical industries.

Using over 75 years of process knowledge, computer added magnetic modeling software and in-house laboratory facilities, Malvern are able to offer flexible and cost-effective machines to suit our customer’s needs and objectives.

Applications

- Separation of weakly magnetic materials from non-magnetic feed streams (Silica/Quartz)

- Separation of Ilmenite / Garnet / precious stones from feed material in Heavy Mineral sand applications

- Removal of ferrous contamination from raw materials used in the manufacture of ceramics and refractories

- Special applications in the food Industries

- Pharmaceutical and Chemical Industries

Magnetic Separator Benefits:

- Low iron content

- Better operating control

- Significantly lower operating costs

- Environmentally safe operations

- Rapid return on investment

Magnetic Separator Benefits:

Low iron content

Better operating control

Significantly lower operating costs

Environmentally safe operations

Rapid return on investment

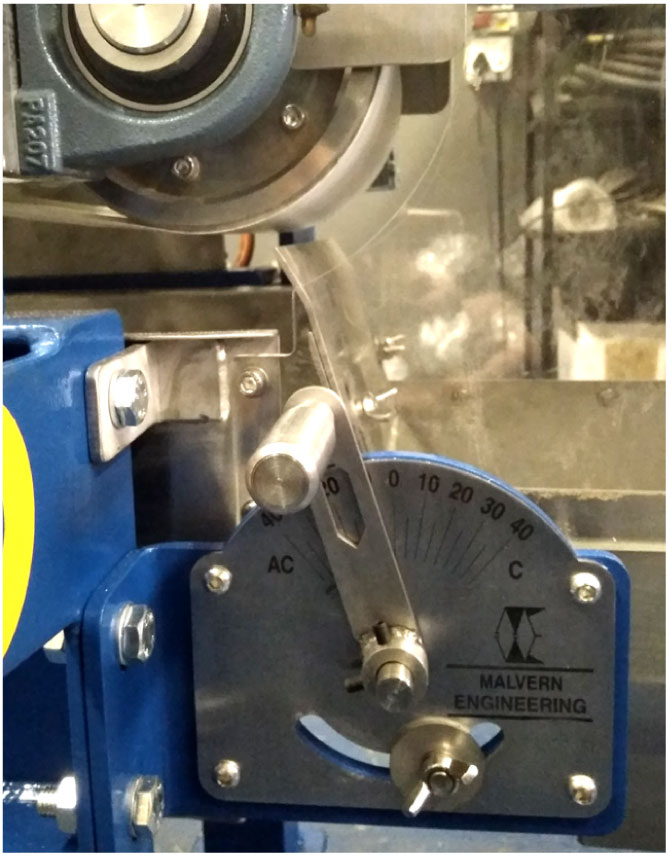

Design

Features

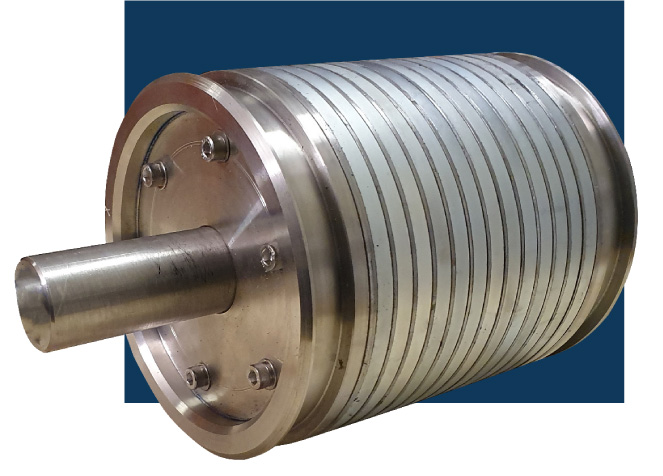

The design of a rare earth roll magnetic separator consisting of a rotating drum made of rare earth magnetic material, mostly neodymium-iron-boron (NdFeB), ensures the optimum combination of magnetic field strength and magnetic gradient to give the most effective separation.

Magnetic Roll Types

Magnetic Rolls

- Roll Diameters: 100mm, 150mm, or 300mm

- Roll widths ranging from 125mm to 1.5 meters

- Available in single or multiple stage configurations ( mag re-run or non-mag re-run)

- The measured magnetic intensity for RE Rolls range: 11000 – 13000G

- Ferrite roll mostly used as scalpers, with ranges 2000-2500G

- Computer simulation programs are used for magnet grade selection and magnet and pole piece thickness

- Roll widths ranging from 125mm to 2 meters

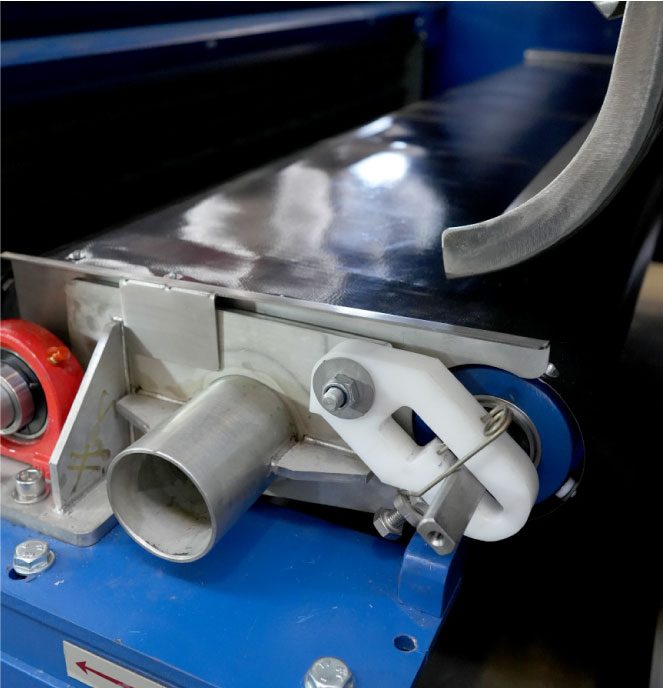

Material Feed System

- Roll and Vibratory Feeders with feed control

- Drive options: Electric motor, Vibrating Motor and electro-magnetic

- Material of construction to suit the specific application

Belts

- PTFE – Coated Kevlar

- Teflon – Coated Fabrics

Drives & Controls

- Independent direct drives for each roll

- Design flexibility allows for Control Panels which could include: Variable speed drive, Speed display, Zero Speed Switch, Feed temperature indicator, Emergency stop

- Direct drive drives

- Reputed make geared-motor

- Control panel with sophistication levels as desired by the customer

Housing

- Enclosures generally manufactured in mild steel, Stainless Steel and dust-free housings are available for special food/pharma and mineral applications

- All material contact surfaces supplied in stainless steel

- Mechanically adjustable splitters with graduated scales

- Provision for the connection of the clients dust extraction system to the machine

- Safety provision for interlocked doors

- Discharge chutes – Mild Steel or Stainless steel

- Design flexibility allows for multiple product splitters and Corresponding outlets, Inspection / maintenance access points

Laboratory

Test Facilities

Malvern Engineering has a well-equipped laboratory at the Johannesburg based office. This facility allows for the quick and efficient testing of customer samples in a controlled environment.

Field Trials

Malvern Engineering is able to supply tailor made pilot scale machines for on-site field trials fully supported by trained and experienced technical staff.