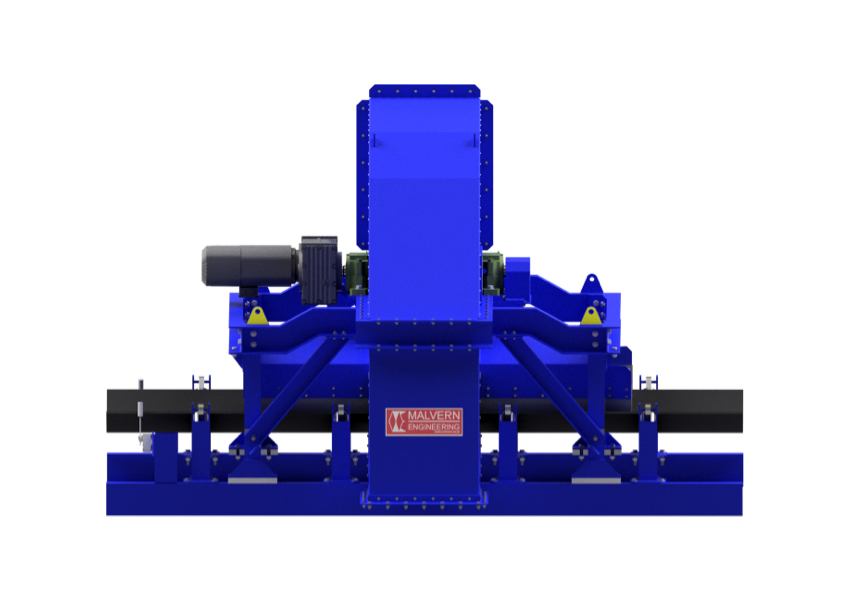

Cross Belt Sampler

Malvern Engineering’s Cross Belt Sampler, also known as a hammer sampler, is meticulously designed in accordance with ISO 13909 standards to provide precise and efficient sampling of bulk materials directly from conveyor belts. This robust system ensures accurate increment collection, essential for quality control and compliance in industries such as mining and mineral processing.